The Essential Role of a **Titanium Fasteners Factory** in Modern Construction

In the rapidly evolving world of construction and manufacturing, the demand for high-quality materials continues to rise. Among these materials, titanium fasteners have emerged as a crucial component utilized by various industries. A specialized titanium fasteners factory plays a significant role in supplying these components, which are renowned for their superior strength, corrosion resistance, and lightweight properties.

Understanding the Importance of Titanium Fasteners

Titanium fasteners are not merely alternative options but vital elements that enhance the performance and longevity of structures. Here are several reasons why they are highly sought after:

- Corrosion Resistance: Unlike traditional fasteners, titanium fasteners exhibit remarkable resistance to rust and corrosion, making them ideal for harsh environments.

- Strength-to-Weight Ratio: Titanium fasteners possess a superior strength-to-weight ratio, making them lighter yet stronger than stainless steel fasteners.

- High-Temperature Performance: These fasteners can withstand extreme temperatures, which is paramount in industries such as aerospace and automotive.

- Biocompatibility: Their biocompatibility makes titanium fasteners suitable for medical applications, providing safe options for implants and other medical devices.

Advantages of Sourcing from a Titanium Fasteners Factory

Sourcing titanium fasteners directly from a dedicated factory offers numerous advantages for businesses, particularly for general contractors who require reliable materials for their projects.

1. Customization

Many large-scale projects demand specific fastener dimensions and functionalities. A specialized titanium fasteners factory can offer custom solutions tailored to meet unique project specifications. This level of customization ensures that every component fits perfectly and performs as expected.

2. Quality Assurance

Factories that specialize in titanium fasteners typically adhere to stringent quality control measures. This means that contractors can trust the integrity of their components, reducing the risk of project delays due to faulty materials. Products undergo rigorous testing to ensure they meet industry standards and client specifications.

3. Cost-Effectiveness

Although the initial cost of titanium fasteners may be higher than traditional options, their durability and performance can lead to significant cost savings over time. By reducing the need for replacements and minimizing maintenance, investing in titanium fasteners proves to be a prudent choice for contractors.

4. Technical Support

Establishing a relationship with a reputable titanium fasteners factory often comes with the added benefit of technical support. This includes assistance with selecting the right fasteners for specific applications and guidance on installation techniques, ensuring that contractors maximize the performance of the materials they use.

Applications of Titanium Fasteners in Various Industries

The versatility of titanium fasteners allows them to be utilized in a wide array of industries. Here are some prominent sectors that benefit from their use:

Aerospace Industry

The aerospace sector heavily relies on titanium fasteners due to their lightweight nature and high strength. These fasteners are crucial in the assembly of various aircraft components, providing safety and reliability in flight.

Automotive Industry

In the automotive world, manufacturers are seeking to reduce vehicle weight without sacrificing performance. Titanium fasteners help achieve this goal, leading to improved fuel efficiency and performance in high-performance vehicles.

Marine Applications

Marine environments can be exceptionally corrosive. Using titanium fasteners in boat construction and repair helps ensure that components remain intact and functional, even in saltwater conditions.

Medical Devices

The biocompatibility of titanium fasteners makes them ideal for use in medical devices, including surgical implants. Their use in such critical applications not only enhances safety but also patient outcomes.

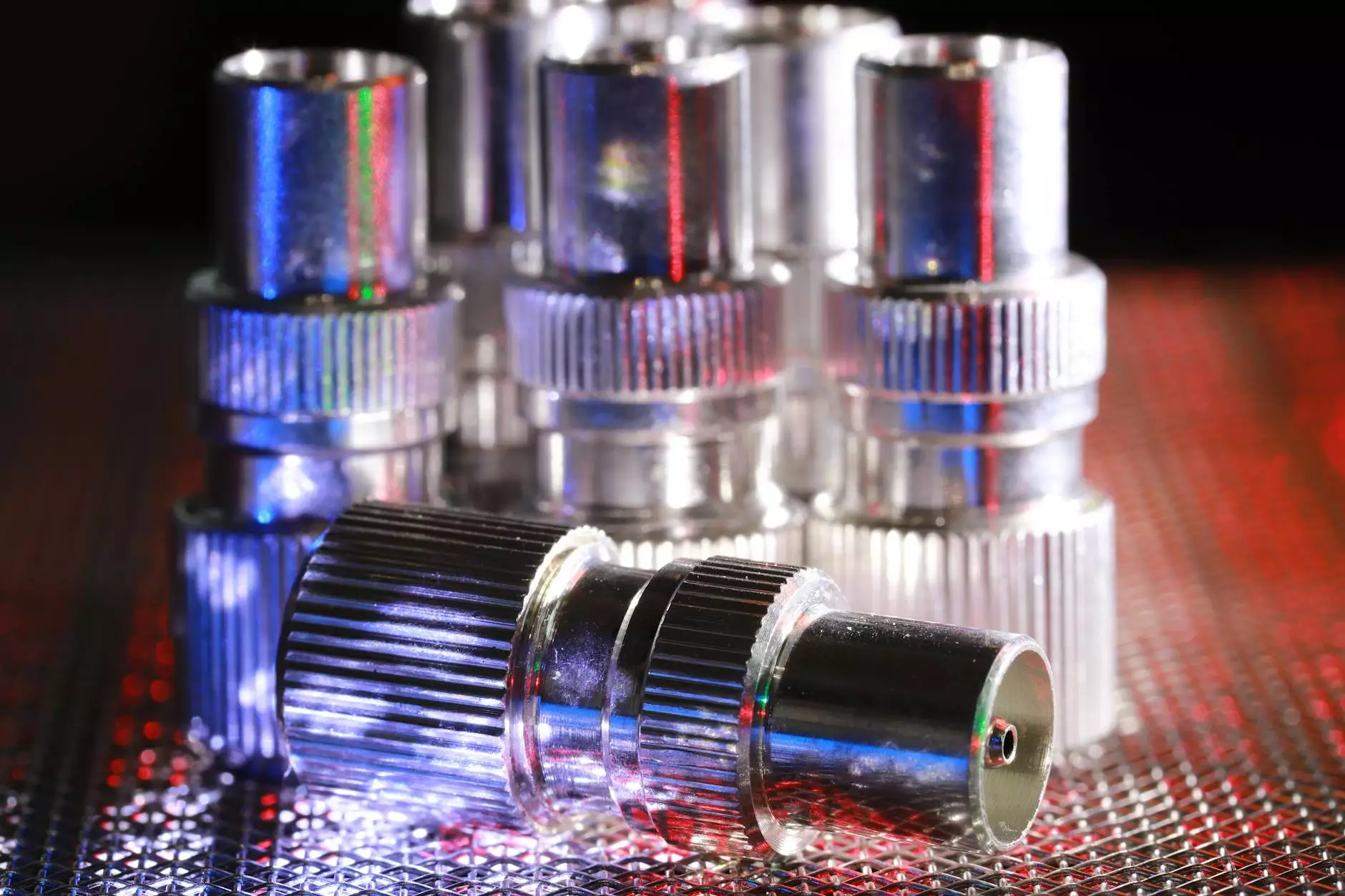

The Manufacturing Process of Titanium Fasteners

Understanding how titanium fasteners are manufactured can provide insight into their quality and reliability. Here is a brief overview of the standard manufacturing process:

- Material Selection: The first step involves selecting high-quality titanium alloys that meet specific project requirements.

- Forging: The titanium material is heated and shaped into the desired form through forging, which enhances its strength and durability.

- Machining: Precision machining is used to create the exact dimensions and threads needed for the fasteners.

- Surface Treatment: Many fasteners undergo surface treatment processes, such as anodizing or coating, to increase their resistance to corrosion and wear.

- Quality Control: Finally, rigorous quality testing is conducted to ensure that each fastener meets industry standards and specifications before leaving the factory.

Future Trends in the Titanium Fasteners Market

As industries continue to innovate, the demand for titanium fasteners is expected to grow. Here are several trends that may shape the future of the titanium fasteners factory landscape:

1. Increased Research and Development

To stay competitive, many manufacturers are investing in R&D to develop new titanium alloys and manufacturing techniques. This will enhance performance attributes like strength, weight, and resistance to extreme conditions.

2. Sustainable Manufacturing Practices

As sustainability becomes a critical issue, titanium fasteners factories are likely to adopt greener manufacturing practices to reduce their environmental impact, from sourcing materials responsibly to minimizing waste.

3. Digital Transformation

The incorporation of advanced technologies such as AI and automation in manufacturing processes is making production more efficient. This helps factories meet increasing demand without compromising quality.

4. Demand for Lightweight Materials

The continuous push for lightweight materials across various industries, especially in aerospace and automotive, will drive the growth of the titanium fasteners market. As companies seek to enhance efficiency and performance, the reliance on titanium fasteners will only increase.

Conclusion

As we've explored, a specialized titanium fasteners factory is indispensable in supplying high-quality components crucial for various industries. Their remarkable features, such as corrosion resistance, high strength, and customization capabilities, make titanium fasteners a preferred choice for general contractors and manufacturers alike. With ongoing advancements in technology and a growing focus on sustainability, the future looks promising for titanium fasteners and the factories that produce them.

For contractors looking for reliable titanium fasteners, partnering with a proven industry leader like titaniumbolts.com can enhance project quality and efficiency, ensuring success in every endeavor.